Brick Paving – Then & Now

As I write this article, I am looking at a 4x8 Unilock Hollandstone Premier paver on my desk. It is uniform in shape, density, and color to the rest of the pavers on the pallet it came from. The beginning of this concrete paver’s story is actually set 7000 years ago on a warm Mediterranean island. The Minoans were Europe’s first advanced civilization. Their island of Crete was a hub for trade and artisans. They built fire kilned brick structures, had methods to pump water, and created the first segmental pavement to engineer their way over loose subsoils. The Romans were next, installing 50,000 miles of paved roads. Amazingly, some of these roads are still in use today!

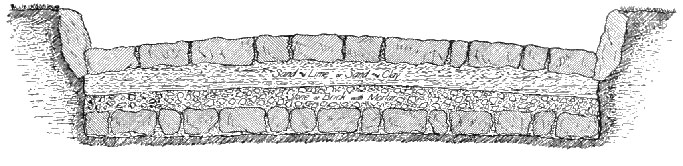

The techniques the Romans employed are similar to what hardscape contractors use today. They excavated a trench and added a layer of larger rubble called “agger”. This base material would be up to 5 feet deep on heavily used roads! Today we generally use crushed limestone, 6-8” thick to provide proper drainage and support a residential driveway.

On top of the agger base a finer layer was laid. This “rudus” layer, made up of sand and gravel, was then compacted. At Christensen’s we offer 2NS sand and #8 chip stone as paver bedding material. Our contractors screed and compact this layer, preparing it for pavers to be laid on top.

The final layer of a Roman road was the “pavimentum”. They used the hardest local rock they could find, sometimes bringing materials in from great distances. The surface paving stones were irregular and difficult to work with.

Fast forward to 1972 when Ed Bryant, founder of Unilock, introduced the UNI-stone paver to North America. A paver revolution has been taking shape ever since. Textures, shapes, finishes, even multi-density options are available. All of these new paver technologies aid with installation efficiency and allow for many specific applications. Really, though, we’re still just digging holes and filling them with rock and sand like the Romans did.